Ceramics is an age-old craft that combines artistry and science to create functional and decorative works. Among the many components and techniques involved in ceramics, silica sand, ceramic decals, and ceramic transfers hold significant importance. These elements are integral to both the aesthetic and structural aspects of ceramic creation.

The importance of silica sand in ceramic production

Silica sand is one of the fundamental raw materials used in ceramics production. Its high silica content makes it invaluable for creating strong and durable ceramic products. Silica sand is primarily used as a flux, reducing the temperature needed to fire ceramics and ensuring a smooth, glass-like finish.

Beyond its structural benefits, silica sand also affects the texture and appearance of ceramics. Mixed into clay bodies or used as a glaze ingredient, it contributes to the ceramic’s overall stability during the firing process. For artisans and industrial manufacturers alike, the uniformity and purity of silica sand are crucial, as they can significantly impact the final product's quality.

What are ceramic decals?

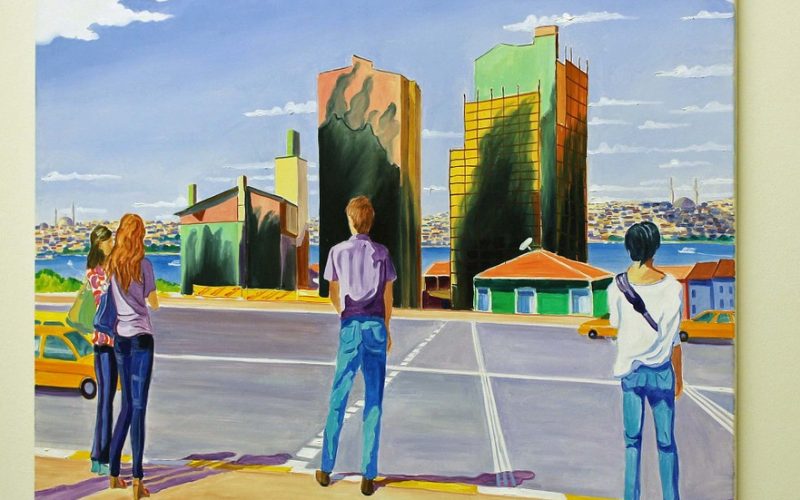

Ceramic decals are decorative designs printed onto special paper that can be transferred to ceramic surfaces. These decals are typically made using mineral-based inks, carefully engineered to withstand high kiln temperatures without losing their vibrancy. This makes them the ideal solution for adding intricate patterns, imagery, or text to ceramics.

Decals are used in a wide range of applications, from fine china to artistic pottery, giving creators the ability to add detailed and repeatable designs that are otherwise challenging to achieve by hand. Once applied, the ceramics are fired in a kiln, which fuses the decal with the surface, ensuring permanence and durability.

Understanding ceramic transfers

Closely related to decals, ceramic transfers are another decorative solution commonly used in ceramics. Transfers allow ceramic artists to apply pre-designed patterns, images, or logos to their pieces efficiently. While often confused with decals, ceramic transfers are slightly different in terms of application and the materials used.

Transfers typically involve a multi-step process that ensures the design adheres uniformly before firing. These tools are especially popular among production potters and manufacturers, as they allow for consistent results across large batches of ceramics. Whether used for commercial branding or artistic purposes, ceramic transfers are a reliable way to personalise ceramic items with precision.

How silica sand and decals come together in ceramics

The interplay between silica sand and decals or transfers in ceramics illustrates the harmonious blend of science and art. While silica sand forms the structural foundation by ensuring durability and a flawless surface, decals and transfers focus on the finer details of embellishment. Together, they enable artisans to create functional yet beautiful ceramic pieces.

For example, a perfectly fired ceramic mug owes its smooth surface and robust structure to silica sand. Its intricate floral design, however, may be the result of high-quality ceramic decals. Without silica sand, the ceramic might not withstand repeated use; without decals, the aesthetic appeal could be pale in comparison.

The growing popularity of ceramic transfers

Over the last few decades, ceramic transfers have gained substantial popularity among small-scale artisans and industrial manufacturers. This rise can be attributed to their cost-effectiveness and the ability to elevate plain ceramic pieces into visually striking creations. Transfers are also environmentally friendly, as they often eliminate the need for excess paints or glazing techniques.

Additionally, digital advancements have allowed for custom ceramic transfers, providing greater freedom for unique and specialised designs. Small business owners, especially those in personalised gift-making or bespoke tableware, heavily rely on this method for its flexibility and professional results.

Why these elements are essential for ceramics

Silica sand, ceramic decals, and ceramic transfers are indispensable tools for contemporary ceramics. Silica sand ensures durability and structural integrity, while decals and transfers add that final artistic touch that can make a piece truly unique. Combined, these elements empower ceramists to balance functionality with creativity.

Whether crafting a simple plate or a high-end decorative vase, understanding how to incorporate these materials and techniques is key to mastering ceramics. Investing time in learning their intricacies can transform the quality of any ceramic project and open the door to endless artistic possibilities.